Panning With Natural Colors – Things to Consider

As consumers continue to push for simple ingredients, brands are taking the leap to convert from synthetic to natural colors. As many developers know, formulating with natural colors can have its share of challenges. This is especially true for confectioners, so I wanted to share some factors in the panning process that can affect natural colors and should be considered when looking to make the switch.

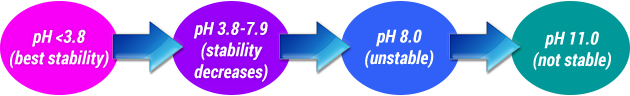

In many cases, brands are looking to match a current synthetic FD&C color used with a natural alternative. If consistency of shade is to be achieved when using natural colors in a production environment, factors regarding the Coating Syrup such as pH, heat, water activity, water quality, and raw materials need to be controlled and monitored.

Certain natural colors are sensitive to heat. Beet, for example will degrade or turn brown with exposure to high heat. In some processes, it has been determined that beet can tolerate a temperature of 80˚C for two hours. Beyond this temperature, the color begins to degrade.

Additionally, some natural colors do not perform well in high water activity systems. Beet is again an example of this. If held in a high water activity environment for long periods of time, it will become colorless. For this reason, beet colors are not used in ready-to-drink beverage applications.

Furthermore, high mineral and heavy metal content in the water source can also affect particular natural colors. Water quality can vary greatly by region and even change depending on season of the year. Therefore, it is always recommended that a purified water source like distilled, deionized, or RO be utilized in the manufacture of the coating syrup.

Lastly, raw materials such as sugar source can impact outcomes in panning. A specific example would be the type of sucrose used. Sugar sourced from beets is more prone to invert compared to sucrose from a cane source. Also, components that may be added such as gums, reducing sugars, PVP, bulking agents, etc. will affect the crystallization of sugar in the panning process. If not monitored, this may lead to an excess of moisture retained in the shell. As this transient moisture moves through the shell, the crystal growth is affected. Because a sugar crystal is opaque, the increased size of sugar crystal growth makes the overall appearance more opaque, giving the appearance of color loss.

In addition to the specifics around Coating Syrup, details of a manufacturer’s process should be

considered when formulating with natural colors.

- Any variation in environmental and physical conditions can cause a difference in color consistency because it affects the overall crystal development. These inconsistencies would also be a contributing factor to “scale-up” variations experienced when moving to a larger scale operation or a different location.

- Environmental conditions in a panning area can affect the overall appearance of a finished product. Humidity (i.e. dew point) and temperature must be consistent.

- Physical conditions in the bed of the pan also need to be consistent. Humidity (i.e. dew point) and temperature must be consistent. Equilibrated mass temperature, bed depth, pan speed, and pan angle (i.e. mixing) will affect color quality.

- Undercoat can also affect color. The majority of natural colors are water soluble and do not have an inherent opacity as a pigment would possess. Therefore, they have less ability to hide the irregularities on the surface. A “bumpy” undercoat will produce a “mottled” appearance on a finished candy product. Many feel this is a result of inconsistent color distribution when in fact the irregular surface area causes an accumulation of color in the low areas of the surface. With repeated coats, the low areas appear darker than the high spots on the surface.

- Proper drying of each sugar syrup application becomes significantly more important with natural colors. If drying is not consistent and thorough, any remaining moisture will travel through the shell, resulting in mottling or graying/dulling.

- During that transit, any water soluble natural color may move with the moisture a

nd accumulate in “hot spots” on the surface, which is a symptom often described as “mottling.”

nd accumulate in “hot spots” on the surface, which is a symptom often described as “mottling.” - Another symptom that could be witnessed as a result of improper drying is “graying” or dulling caused from residual moisture that is trapped under the impermeable polishing layer. This symptom can sometimes occur immediately or it can develop after the candy is packaged.

- During that transit, any water soluble natural color may move with the moisture a